ENVE COMPOSITES

Carbon Components and Bikes

Founded in 2007 out of a desire for a better ride, ENVE strives to offer consumers products without compromise. ENVE designs and manufactures 100% of its wheels at its facility in Ogden, Utah, USA. Manufacturing, assembly, design, R&D and its test lab are all under one roof, providing unparalleled levels of visibility, control and connectivity which would be impossible under any other circumstances.

Working under the same premise, ENVE COMPOSITES seeks to ensure that each of its products strikes the perfect balance between lightness, strength, stiffness and aerodynamics.

The ENVE team is made up of daring people, engineers and innovators, driven by their passion for cycling. ENVE is a collective of people capable of creating the best carbon fibre products in the world.

Working closely with the most prominent frame builders of our time and the world's best athletes, combined with industry leading carbon technology, allows ENVE to deliver products which are light, stiff and durable. Born out of the desire for a better ride, ENVE strives to offer its customers uncompromising products and the highest quality guarantees.

ENVE is so confident in the quality of its products and is so committed to the consumer, that it offers a lifetime warranty on all its wheels.

The Wheels

In designing Enve carbon fibre wheels, its engineers set out to produce the fastest wheels on the planet. "FASTNESS" lives at the intersection of stiffness, lightness and durability. All of these factors contribute to a wheel's handling characteristics. Each piece of the puzzle must be carefully balanced to create the best experience. Anyone can make a stiff, durable, heavy wheel, and most can make a lightweight wheel that is not durable. However, combining all three is the real engineering challenge.

There are several factors that contribute to making a wheel that meets all these criteria. Unidirectional carbon fibre allows for fine tuning in the rolling process, which defines the ride quality and characteristics of the wheel, however the finishing touches and fit are perfected in the wheel building process. Each handmade ENVE wheel balances all elements to optimise stiffness, weight and strength.

SES road wheels combine lightness, stiffness and aerodynamics to an unrivalled degree. They are incredibly fast thanks to advanced aerodynamics developed in the wind tunnel and their exceptional stiffness-to-weight ratio allows for electrifying acceleration and handling response. What's more, in every profile they redefine aerodynamic wheel stability in strong crosswinds to the point where you barely notice the wind, let alone worry about it.

TECHNOLOGIES AND PATENTS

Enve's free thinking has led to numerous patented technologies that result in faster, stronger, lighter and more aerodynamic wheels and components.

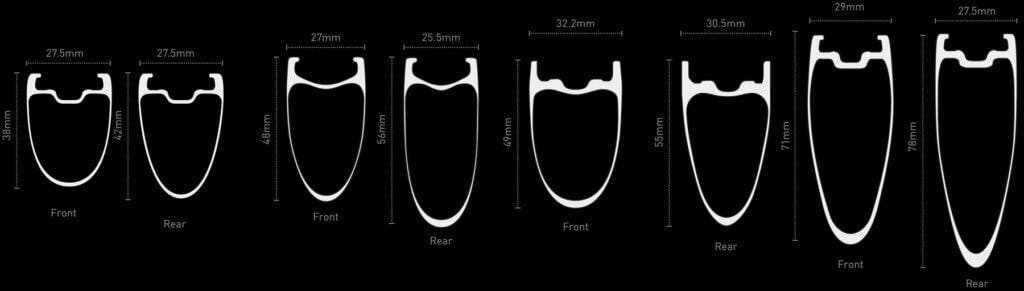

- SES, aerodynamic shape with unequal profiles between front and rear wheel.

- Moulded spoke and valve holes.

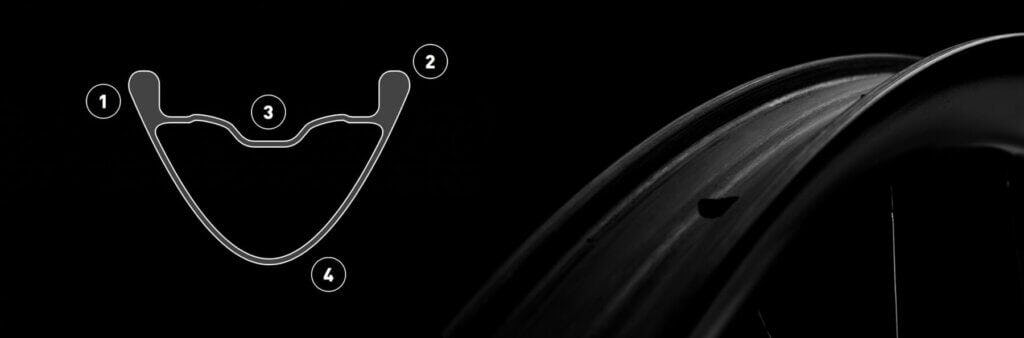

- ‘Hookless’ inner walls.

SES: SMART ENVE SYSTEM

Aerodynamics Patent #US 8,757,733155

More than ever, aerodynamics is the name of the game on the road or on the race track. All Enve road and triathlon wheels are developed on the bike as an integrated system. Wheels are tested on multiple frame designs in order to produce a net reduction in aerodynamic drag regardless of which bike is used.

This unique approach to testing results in a wheel system that incorporates specific shapes and profiles for the front and rear wheels as airflow interacts with the front and rear of the bicycle in different ways.

ENVE SES 3.4 DISC: The most climbing version of ENVE. The 3.4 DISC is possibly one of the best climbing wheels on the market, perfectly combining stiffness, weight and aerodynamic efficiency. This wheel will delight riders who want to fight gravity on the steepest slopes.

- FRONT RING PROFILE: 38mm

- FRONT RING WIDTH: 21mm

- REAR RING PROFILE: 42mm

- REAR RING WIDTH: 21mm

- SET WEIGHT: starting at 1399

ENVE SES 3.4: The non-disc version of the brand's climbing wheel. This wheel will delight cyclists who want to fight against gravity on the steepest slopes.

- FRONT RING PROFILE: 38mm

- FRONT RING WIDTH: 21mm

- REAR RING PROFILE: 42mm

- REAR RING WIDTH: 21mm

- SET WEIGHT: 1409 grams and upwards

ENVE SES 4.5: This wheelset minimally increases the weight of the set, but we gain almost 1 centimetre of profile in each rim. This wheel will further improve the aerodynamics of our bike, however whilst maintaining good sensations on the mountain passes.

- FRONT RING PROFILE: 48mm

- FRONT RING WIDTH: 18.5mm

- REAR RING PROFILE: 56mm

- REAR RING WIDTH: 17mm

- SET WEIGHT: starting at 1455 grams

ENVE SES 5.6 DISC: This wheelset is possibly one of the delights of the fastest cyclists. A wheel designed to ride at high speed, coping with low gradient climbs with solvency. An ideal wheel for sprint events, or for medium distance Triathlon events.

- FRONT RING PROFILE: 54mm

- FRONT RING WIDTH: 20mm

- REAR RING PROFILE: 63mm

- REAR RING WIDTH: 19mm

- SET WEIGHT: 1535 grams and upwards

ENVE SES 7.8 DISC: We can assure you that the 7.8 is one of the most aerodynamically efficient wheels on the market. The rim design will allow you to ride at high speed on favourable terrain, without penalising you on gusty windy days.

- FRONT RING PROFILE: 71mm

- FRONT RING WIDTH: 19mm

- REAR RING PROFILE: 78mm

- REAR RING WIDTH: 19mm

- SET WEIGHT: from 1651 grams

Smart Enve System. SES AR

With the growing trend towards more balloon tyres, ENVE has developed the AR or ALLROAD version. The ENVE SES AR models have the same objective as the ENVE SES, seeking the best balance between weight, stiffness, and efficiency, without compromising reliability. The SES AR wheels share the same construction technology as the ENVE SES, in terms of the quality of the carbons used, however we can tell them apart at a glance due to their HOOKLESS nature compared to the traditional HOOK system of the ENVE SES. The HOOKLESS system is a legacy of the mountain wheels, this allows the tyre to be better beaded, essential for the Tubeless systems that are becoming more and more popular among professional teams and amateurs. SES AR DISC rims cannot be mounted on tyres with a balloon size of less than 28mm. They have become a benchmark in ALLROAD and FASTGRAVEL, due to their competitive weight and high efficiency.

ENVE SES 3.4 AR DISC: It could be said that it is the twin sister of the ENVE 3.4 DISC. The purpose sought in these wheels is the same as in that model, but with the virtue of being able to mount somewhat wider tyres, providing the ability to ride on uneven surfaces with greater comfort and be able to mount gravel tyres.

- FRONT RING PROFILE: 38mm

- FRONT RING WIDTH: 25mm

- REAR RING PROFILE: 42mm

- REAR RING WIDTH: 25mm

- SET WEIGHT: starting at 1399 grams

ENVE SES 4.5 AR DISC: It could be said that it is the twin sister of the ENVE 4.5 DISC. The purpose sought in these wheels is the same as in that model, however with the virtue of being able to mount somewhat wider tyres, providing the ability to be able to ride on uneven surfaces with greater comfort, and mount gravel tyres.

- FRONT RING PROFILE: 49mm

- FRONT RING WIDTH: 25mm

- REAR RING PROFILE: 55mm

- REAR RING WIDTH: 25mm

- SET WEIGHT: from 1368 grams.

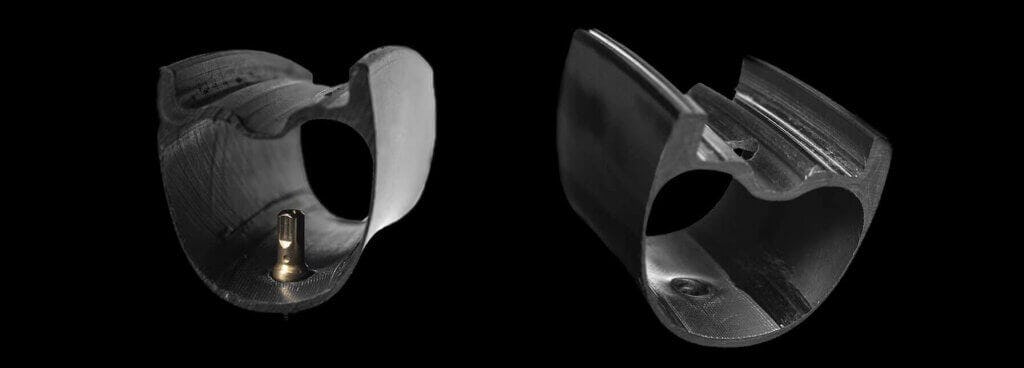

MOULDED SPOKE AND VALVE BORES

Patent #US 8,313,155

ENVE directs the fibres around the hole without cutting them, which increases the strength of each hole. This technique pays big dividends in the final product by allowing for a lighter spoke face while improving the strength of the rim. Thanks to this process, the spoke holes are able to maintain a higher spoke tension, which greatly reduces the risk of the spokes becoming loose and the need to constantly regrind the wheels. The process of moulding the spoke and valve holes results in stronger and lighter rims.

HOOKLESS

ENVE's Hookless is the result of 2 years of development of carbon mountain bike rims to address this scenario. The result is a rim shape that features a wider leading edge. This wide surface area creates a more forgiving platform on which the tyre can bottom out. In addition to greatly improving the tyre's performance and reliability, the wide Hookless bead design reinforces the leading edge of the rim and allows for greater impact resistance.

M Series MOUNTAIN BIKE

ENVE's goal in the mountain wheel series is to make our bike and us, perform at the highest level. The rims are always made of carbon, regardless of the MTB modality: cross country, trail, enduro, all mountain or downhill. As a premise, ENVE seeks to achieve the best compromise between lightness, stiffness and reliability. The ENVE M rims are made of 100% carbon and are designed in such a way as to try to minimise puncture failures as much as possible. The rims use HOOKLESS technology, which allows for better tyre beadability, and to ride at lower pressure without the risk of undercutting the tyres. Their impact resistance has been tested to the limit during the world's most demanding competitions. They are so confident in the quality of their products and so committed to the end consumer, that ENVE offers a lifetime warranty on all their wheels.

ENVE's range of mountain wheels is available in 29" and 27.5".

ENVE M5: The XC and XCM wheel. A wheel light enough for maximum speed, yet tough enough for everyday riding. The M5 is designed to tackle the most demanding climbs and enjoy fast descents.

- INSIDE RING WIDTH: 25mm

- SET WEIGHT: from 1340 grams.

- NUMBER OF HOLES: 24/24

ENVE M6: The M6 is the trail wheel. With a very competitive weight that makes it easy for you to control while going fast, uphill and downhill. The ENVE M6 offers instant acceleration and lively cornering.

- INSIDE RING WIDTH: 30mm

- SET WEIGHT: from 1457 grams.

- NUMBER OF HOLES: 28/28

ENVE M7: The M7 is the Trail wheel designed specifically for the most demanding cyclists.

- RING INTERNAL WIDTH: 30mm

- SET WEIGHT: from 1849 grams.

- NUMBER OF HOLES: 32/32

ENVE M9: The M9 is the enduro and downhill wheel designed to tackle the world's most demanding descents. Put to the test in the Downhill World Cup, Red Bull Rampage races and the Enduro World Series.

- RING INSIDE WIDTH: 30mm

- SET WEIGHT: from 2108 grams.

- NUMBER OF HOLES: 32/32

GRAVEL. ENVE FOUNDATION AG25 and AG28

Carrying the best material is key to a successful adventure into uncharted territory. With the experience of developing the iconic G Series and M Series, they have created a performance enhancing package incorporated into the new AG range. Features such as a wide bead and hookless rim, use of the best carbon, external nipples, and the new Foundation Road hub, make the AG one of the most complete and quality/price gravel wheels on the market. The ENVE FOUNDATION AG will take our bike to an even higher level of performance, which means more fun for us. In this series we can choose between 700c or 650b diameter.

AG25: The twin sister of the renowned G23. With a 700 diameter, this agile, comfortable, yet fast wheel will make long days on the road exhilarating and inspire absolute confidence under all circumstances.

- RING DIAMETER: 700 mm

- INSIDE RING WIDTH: 25 mm

- RECOMMENDED TYRE SIZE: 32c

- SET WEIGHT: from 1480 grams.

- NUMBER OF HOLES: 24-24

AG28: The twin sister of the well-known G27 with 650b diameter. With the 650B wheel diameter we have wider rims, which will allow us to ride at lower pressure. This makes a 650b gravel bike more confidence inspiring on rough terrain.

- RIM DIAMETER: 650b

- RING INSIDE WIDTH: 28 mm

- RECOMMENDED TYRE SIZE: 47mm to 2.25".

- SET WEIGHT: from 1480 grams.

- NUMBER OF HOLES: 24-24

ENVE COMPOSITES

In addition to offering a wide range of carbon wheels for our bicycles, ENVE offer a large number of carbon components to equip and lighten our bicycles.

The main objective of ENVE is to make the cyclist improve his experience on his bike. Therefore, depending on the use and the discipline we practice, ENVE will offer us a product that will adapt perfectly to our needs.

With the upgrade of these components, we will not only improve the performance of our bike and improve our sensations on it, however we will also get a fully customised and exclusive bike.

ENVE offers us a wide range to customise our road bike, mountain bike, and gravel/CX. Within each of these cycling modalities, we will be able to choose between handlebars, stems, seatposts, forks, tyres, bottle cages.

WARRANTY

Many brands today boast that they offer a "lifetime warranty" on their products, but is this really true?

When it comes to lifetime warranty, there is not always fine print. This warranty is usually for a manufacturing defect, but not for the use of the product. Any product, whatever it is, and whatever material it is made of, suffers fatigue due to wear and tear, conditioning its performance and resulting in breakage due to stress. Most brands, when a component has broken due to fatigue, despite announcing that they offer a lifetime warranty, never cover it. Rather they may offer a crash replacement, or a special price to purchase a new product of that brand. Most consumers are used to giving in to this situation. ENVE goes further. It is a brand 100% committed to the cyclist, and 100% sure that their quality standard is at the highest level, that they offer a lifetime guarantee against any circumstance in their rims. Yes, that’s correct. ENVE offers free rim replacement, even in the event of an accident, even if the brand has nothing to do with the damage to the rim. This type of guarantee means that the cyclist can enjoy the product without worrying about damage to the rim. In this situation, the investment in ENVE wheels is more than justified.

THE CONCLUSION OF ENVE

ENVE is a growing brand with a strong focus on research and development. The development of carbon parts and use of new technologies makes their products of the highest quality. One of their strong points as we have said is their offering a lifetime guarantee against accidents.

Enve wheels can already be seen on professional equipment and can also be found in our shop, in addition top all of the components manufactured by Enve.